The Effect of Daylight

Rebecca Ellison looks at the effects of UV damage, thermal expansion, and drying on fine furnishings, fittings and finishes.

Natural daylight is considered the best form of illumination for interior fittings and finishes of historic buildings, not least because it reveals their true colours. However, daylight is also responsible for the degradation of objects, particularly those made from organic material. This article explains the mechanisms and effects of this deterioration and draws attention to the objects at greatest risk. It also highlights the importance of controlling exposure in order to prevent damage and it details some of the methods available.

What is Light?

Light is a form of energy known as electromagnetic radiation. It ranges from very short wavelength gamma radiation at one end of the spectrum, to long wavelength radio waves at the other. Visible light ranges from blue-violet to red and from a wavelength of 400-760nm*. Ultra violet (UV) radiation has a shorter wavelength than visible light (0-400nm) and infra-red (IR) radiation has a longer wavelength (>760nm).

The wavelengths in daylight which cause most damage to interior fittings and finishes include visible light and ultra violet light. This is because the energy content of light varies according to its wavelength: the shorter the wavelength the higher the energy content. Therefore, UV radiation has more energy than blue visible light, which in turn has more energy than red light and so on.

Fortunately, short wavelength radiation is not penetrative, and in practice UV up to 300nm is absorbed by ozone in the earth’s atmosphere. By the time sunlight reaches the surface of the earth the sun’s radiation consists of approximately 50% visible light and just 3% UV radiation. Window glass prevents the passage of wavelengths up to 325nm, and the most harmful effects UV and visible light are confined to the surface of an object for the same reason.

At an atomic level, when sunlight falls on an object, the high energy provided by this radiation excites electrons, in some cases causing them to be displaced from bonds between atoms, particularly in organic compounds, as detailed in the table. This process can cause material to deteriorate and colours to fade. Objects also heat up causing their materials to expand and contract, often at different rates to each other. The differential movement can lead to stress resulting in damage to the structure of rigid materials. They can also dry out, again causing differential movement as well as cracking and crazing of some surfaces.

Infra-red radiation can also provide the necessary energy to displace electrons, contributing to the deterioration process. IR also raises temperature, which dries out objects.

The Effect Of UV Radiation On Materials And Fittings

Oil paints and varnishes

Drying oils, such as linseed oil, are used as the medium for oil paints. Like all but the most simple organic compounds, drying oils are formed of the long carbon-chain molecules known as polymers. When exposed to UV radiation in daylight, the long molecular chains become unstable and a variety of reactions take place including ‘free radical chain reactions’ and ‘auto-oxidation’ as described in the Chemistry table below. As a result the drying oils ‘polymerise’ to a semi-solid state. They are also bleached by light and tend to increase in transparency over time. This is because the refractive index increases, becoming closer to that of the pigment. Where oil paintings are affected, alterations made by the artist are sometimes revealed as the oil medium becomes increasingly transparent, a phenomenon known as ‘penti-menti‘.

Pigments in an oil film are often totally surrounded by the medium. Generally this prevents UV from causing deterioration such as fading, and only thinly applied glazes of lake pigments (dyes struck onto an inert base, such as madder lake and quercitron) are susceptible.

Both natural and synthetic varnishes also undergo free radical chain reactions initiated by UV. This leads to increased polarity, resulting in solubility only in polar solvents. This can risk solubility to underlying paint layers during varnish removal. In addition, auto-oxidation leads to cracking, hazing, loss of gloss and yellowing.

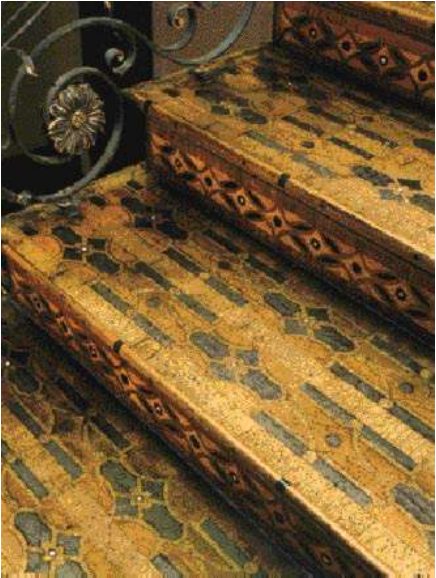

Wood

Wood contains cellulose, a high molecular weight polysaccharide. Cellulose undergoes auto-oxidation in the presence of UV radiation (1) leading to bleaching of the surface Cellulose itself does not absorb UV, however, lignin, hemi-celluloses and some dyes and pigments act as photo-sensitisers. (Photo-sensitisers absorb UV radiation and transfer the energy to the cellulose, initiating a reaction.) As a result some of the long molecular chains break up, lowering the degree of polymerisation, and weakening the material. Nevertheless, deterioration is unlikely to have a significant effect on the structural integrity of joinery because joinery is usually solid and auto-oxidation only occurs at the surface.

Textiles

Textiles made from natural fibres also contain a high proportion of cellulose, which deteriorates in the same manner as the cellulose of wood. As textiles are far more fragile objects than joinery and the fibres often become brittle, leading to rapid structural deterioration.

Pigments and dyes

The materials and fittings which are most vulnerable to deterioration when exposed to visible as well as UV radiation include naturally dyed textiles, tapestries, and costumes, dyed leather, paintings in distemper media, gouache and watercolours, prints and drawings, and wallpapers (2). Damage occurs on two fronts; loss of colour and pattern, and the structural deterioration of the fabric, as follows.

The pigments and dyes used to colour these objects are highly susceptible to fading. In addition to absorbing visible radiation, there is no protective medium surrounding the pigment particles or dyes to prevent radiation from initiating ‘auto-oxidation’, a deterioration mechanism which is explained further in the table. This quickly leads to a breakdown of the colour centres in the pigments and causes fading. Natural dyes are particularly susceptible, as by definition they dissolve in a medium imparting colour by staining and being absorbed. Fading of pigments affects the comprehension of surface decoration and is an irreversible form of damage.

Natural textiles and paper are used as supports for the majority of these sensitive decorative finishes. As described above, textiles contain a large amount of cellulose, as does paper. They become brittle and discolour, becoming darker, due to auto-oxidation. Again damage is not reversible and interventive treatment is the only option.

Protection

To minimise deterioration, controlling the exposure of objects to radiation is of paramount importance. However, the need to set limits for visible light must be balanced against the need to see objects.

Ideally, the recommended illumination for moderately sensitive material is of 200±50 lux*, and the proportion of UV in daylight should not exceed 75µW/lm* for all materials. Sensitive materials should receive no more than 50 lux. These are ideals and it may be more practical to display moderately sensitive material at lux levels in the low hundreds. They should be kept away from direct sunlight and UV filtered to 75µW/lm. Lux levels and UV content for sensitive material does need to be tightly controlled to limit damage. It is recommended to avoid direct sunlight, to prevent an excessive rise in temperature.

A variety of methods are available to help achieve and maintain control of daylight. A number of products are discussed below. Some filter UV, whilst others reduce visible light and solar heat.

Daylight filters

Filters reducing UV, visible light or solar heat often filter some of the wavelengths in visible light. The effect this may have on the colour of transmitted light should be considered alongside their protective value as, in most situations, the colour rendition of objects in interiors is vitally important. Colourless UV filters prevent the passage of all UV radiation below 400nm, whilst allowing the transmittance of all visible radiation. Filters with a yellow tint absorb all UV radiation and short wavelength visible radiation which cause some natural dyes to fade, but they also change the colour rendition.

Laminated glass contains a layer of polyvinyl-butyral (PVB) sandwiched between two layers of window glass. Grades with UV absorbers dispersed in the PVB are available. The PVB also renders the glass shatter resistant. However, laminated glass is expensive and it implies either replacing existing glazing, or fitting secondary glazing. This adds further expense and may not be appropriate for historic buildings.

Self-supporting acrylic sheeting is available in grades containing UV absorbers. (Acrylic is the generic name given to polymethyl methacrylate, a synthetic polymer produced from acrylic and methacrylic acids.) This option is cheaper than laminated glass, but it can have a yellowish tint, it is easily scratched and it can cause problems with glare. As with laminated glass, this material implies either replacing existing glazing or fitting secondary glazing, which may not be aesthetically appropriate.

Solar films are self-adhesive polyester sheets, usually acetate. They can reduce transmittance of UV radiation, visible light or solar heat or a combination of the three. They are cut to size and are fitted either internally or externally. They do not require replacement of existing glazing, are relatively cheap and easy to apply. Unfortunately they are easily scratched and are not durable if applied externally.

Varnishes containing UV absorbers can be painted onto the inside of window glass. This option is useful for windows containing very small or large panes of glass, where it is impractical to apply films, or to uneven glass. Varnishes are inappropriate for windows exposed to extreme temperatures, causing cracking and condensation, where the water causes lifting. Varnishes are also easily abraded.

Sun-blinds and other methods of control

In addition to filters, other methods of reducing light are available including sun-blinds and curtains.

Sun-blinds are normally manually controlled blinds which should be lowered in direct sunlight and adjusted in response to the sun’s movement around the building to inhibit direct sunlight, whilst still allowing a view outside. They should also be adjusted according to the light levels in the room – a light meter is a useful aid – and they must be well fitting to prevent light shining through. The blinds are usually made of a white or cream coloured fabric which gives a diffuse light whilst inhibiting the passage of direct sunlight. Cream blinds give a warmer light. Good quality blinds will last many years. One disadvantage is that they require frequent and rigorous adjustment to ensure effectiveness.

Sun curtains can be used to reduce light in situations where blinds are inappropriate for aesthetic reasons. Thicker material obscures more light. They should be well fitting to prevent shafts of light entering the building. Unfortunately, curtains must be completely closed when in use, preventing a view outside. However, good quality curtains may last many years.

Careful positioning of furniture and other objects in the interior can also help minimise their deterioration. Placing them out of the path of direct sunlight is important because direct light causes far more damage than diffuse light.

The Effect Of Daylight – Click on the link bellow to read the article ‘The Effect of Daylight’